- Supercool

- Posts

- 🌐 From American Factories to Global Rooftops—Climate Tech Goes Mass Market

🌐 From American Factories to Global Rooftops—Climate Tech Goes Mass Market

Enphase upgrades homes into mini power plants, modernizing the grid with smart solar, storage, and software.

Raghu Belur and the American Dream

Raghu Belur defines the American Dream—an immigrant founder who rewired the grid by starting at its edge.

Raghu came to the U.S. as a young man from India in 1990 to study electrical engineering at Texas A&M University. He moved to Silicon Valley. Worked at half a dozen startups. Some scaled, others flopped. Yet, the journey taught him essential Silicon Valley maxims:

Semiconductors and software disrupt old industries.

Centralized systems give way to decentralized ones.

Scale follows when you design for cost, reliability, performance, and, above all, the customer.

In 2006, Raghu took everything he’d learned and set out to build the future. Not all at once. That wouldn’t be practical.

He and co-founder Martin Fornage focused on a single idea no one thought possible: giving every solar panel its own brain.

Instead of one big inverter on the side of a house, what if each panel had its own microinverter? A semiconductor-based device that could turn DC power to AC, optimizing energy generation at the source. Panel by panel. Home by home. Making each panel smart, efficient, and self-reliant.

That idea became the launch pad.

Less than two decades later, Enphase Energy has shipped over 80 million microinverters to customers in more than 160 countries, operating on 5 million rooftops.

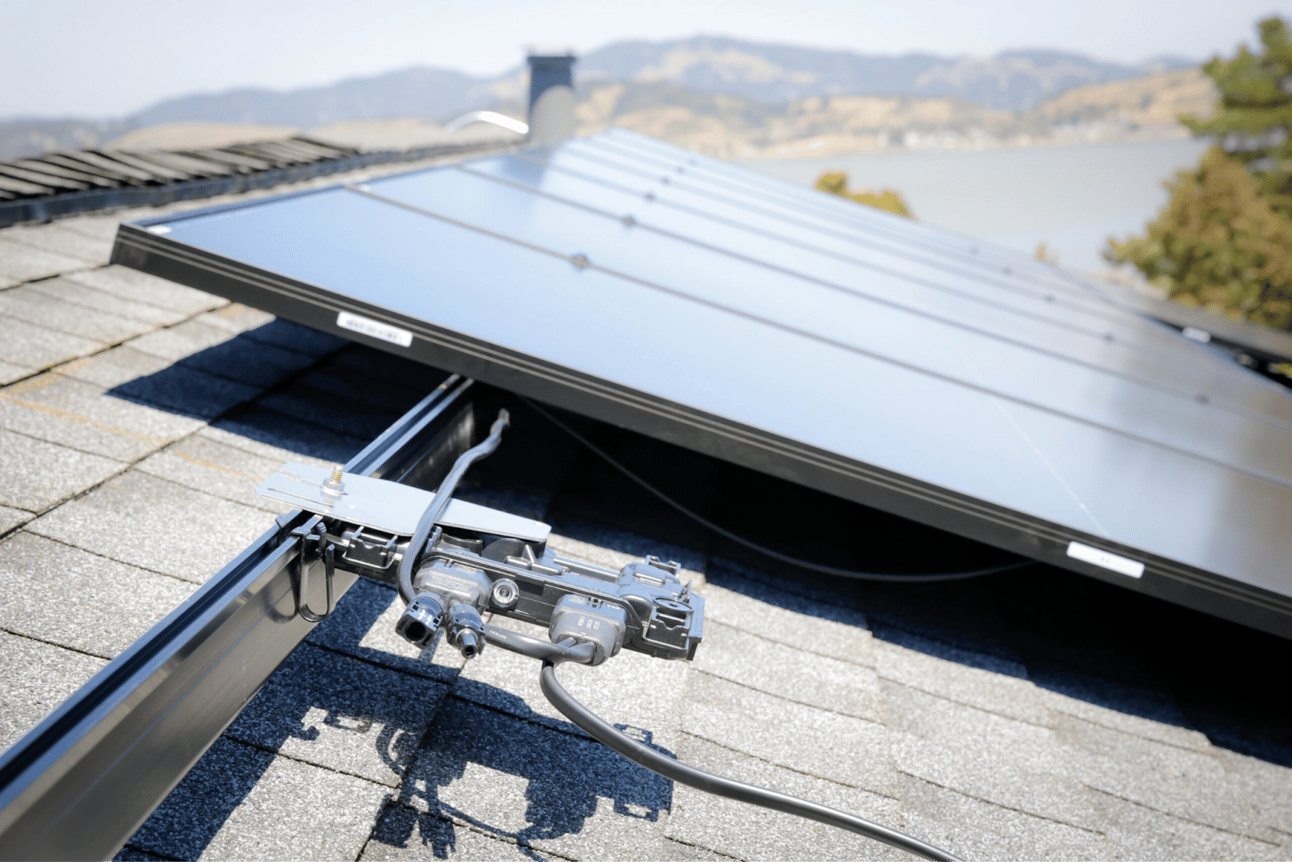

An Enphase microinverter awaits its solar panel on a rooftop.

85% of those inverters are now manufactured in Texas and South Carolina. That’s American-made clean energy technology supporting U.S. jobs and supplying both domestic and global markets.

At a time when the U.S. is trying to rebuild its manufacturing sector and boost energy production, Enphase is already doing it.

Now publicly traded and valued at $5.5 billion, Enphase is part of a bigger story:

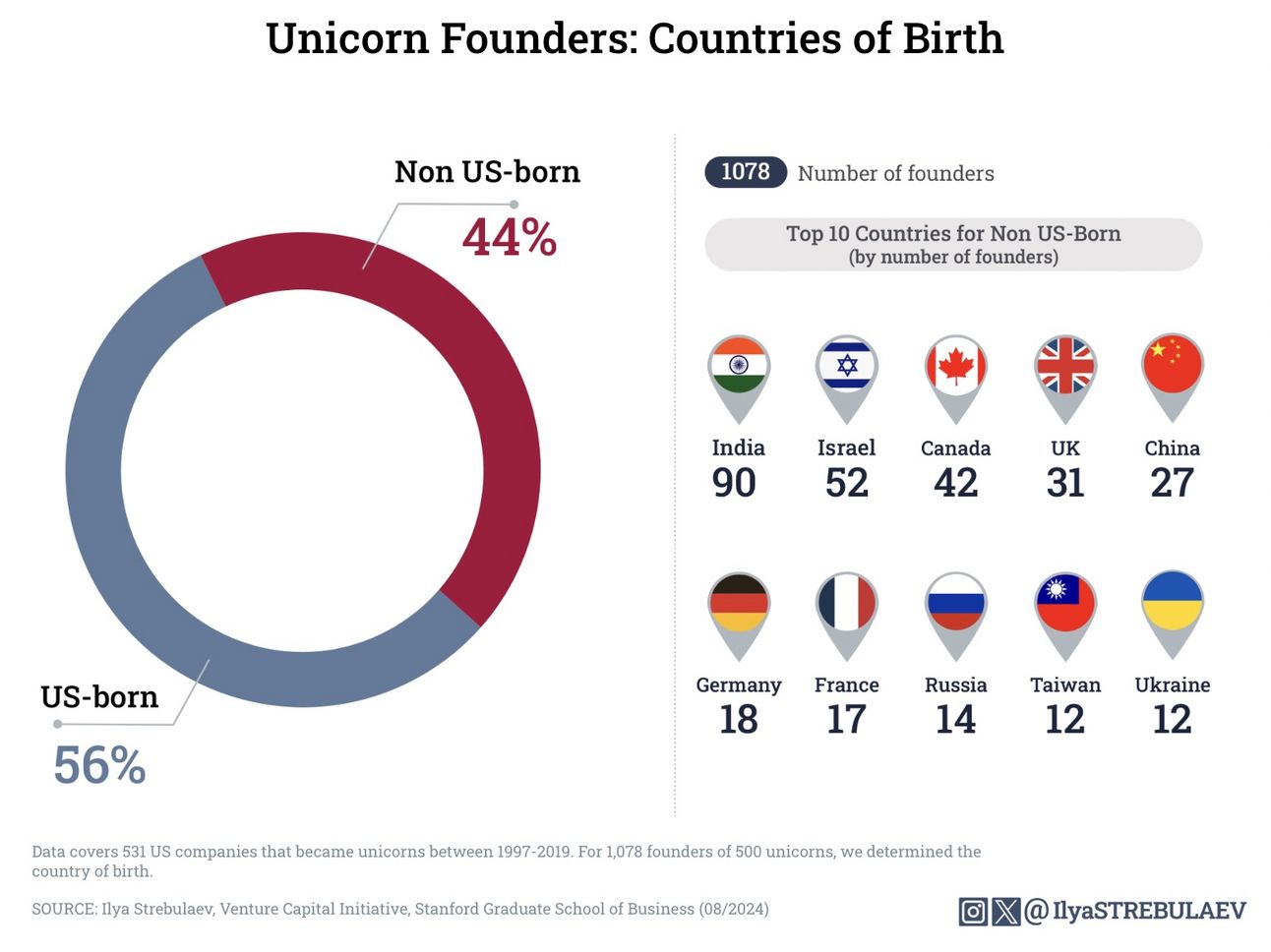

44% of U.S. tech unicorns are built by immigrants. Raghu and Martin are in those ranks.

But that’s only half the story.

It’s Still Edison’s Grid

What Raghu and Martin saw back in 2006 wasn’t just an opportunity in solar. It was a structural flaw in how we deliver power.

The grid is still built on 20th-century assumptions: power flows one way, from big central plants to passive customers. It’s rigid. Fragile. Overloaded.

“If Edison, Tesla, or Westinghouse were walking down the streets of Fremont, California, and they looked up at the infrastructure, they would probably recognize all the elements of it,” Raghu says. “And that’s the problem.”

The rise of electric vehicles (EVs), heat pumps, and AI data centers is straining a system that was never designed to handle such high power loads. And it can’t expand fast enough to meet the moment.

The energy future needs a new blueprint.

From Utility Customer to Mini Power Plant and Grid Partner

Raghu and Martin knew that one day homes would do more than consume energy. They would generate, store, and intelligently manage it. They would share it with the grid, and yes, with their neighbors.

Homes would effectively become mini power plants.

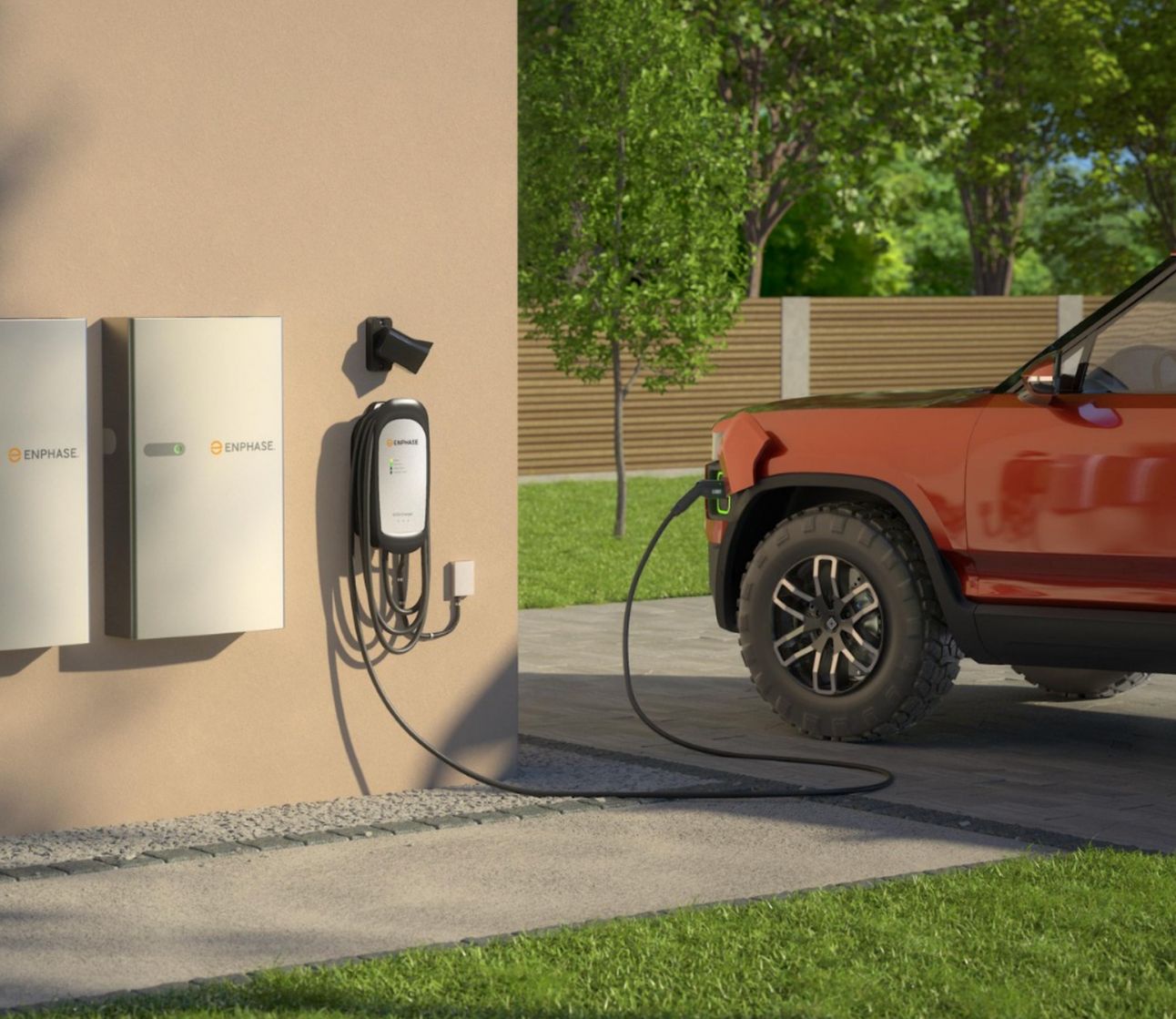

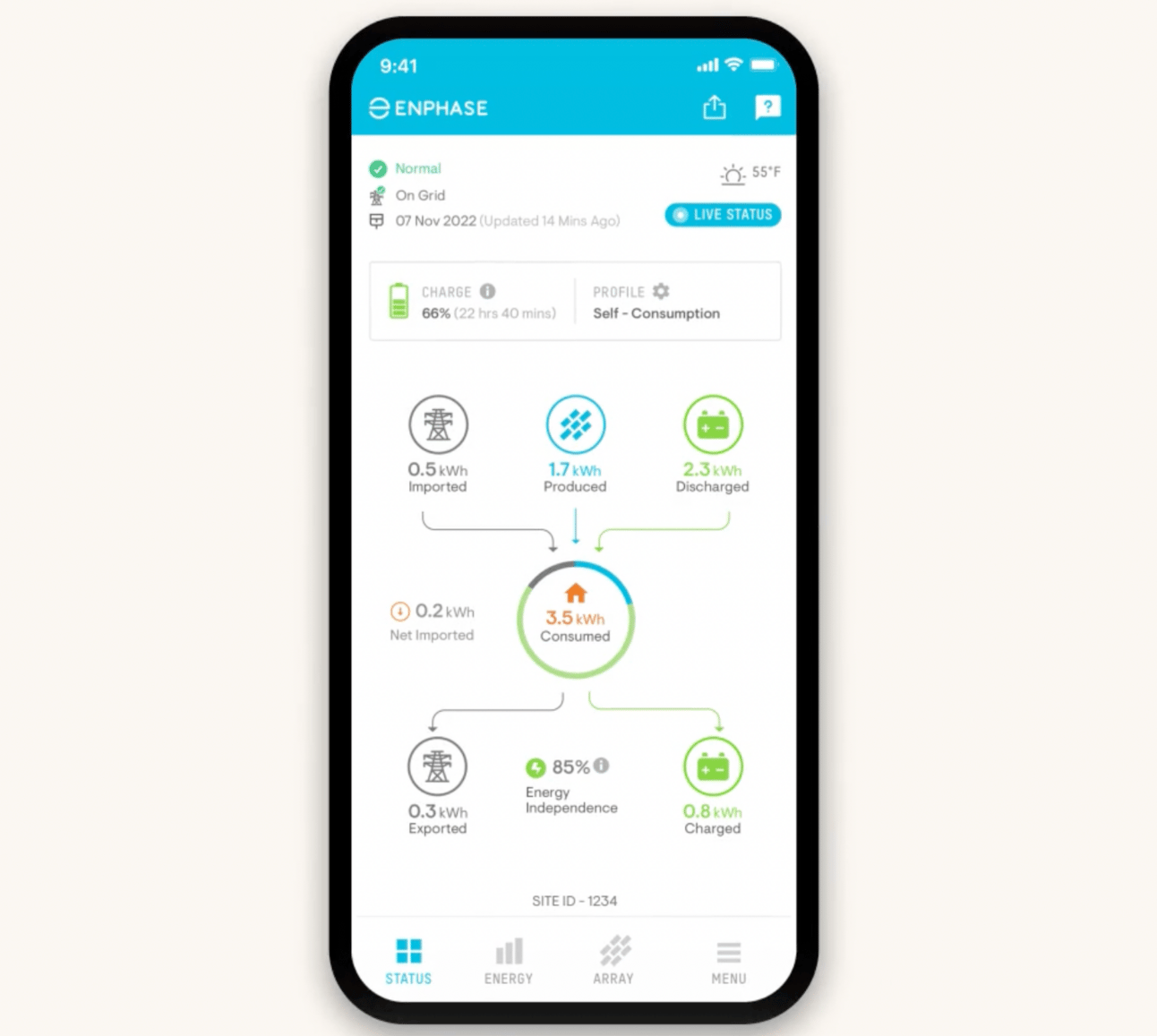

So Enphase expanded beyond inverters. Solar, batteries, EV chargers, and smart home energy management software are now integrated into a seamless system that homeowners can control through a single app—or not (they can also allow Enphase intelligence to run on autopilot in the background and pay the app no mind at all).

Enphase batteries and EV chargers are integrated into its intelligent management system.

“It has to be simple on the outside,” Raghu says. “People don’t want to manage energy—they want peace of mind.”

Enphase coordinates devices in real time, balancing comfort, efficiency, and savings.

Customers can make, use, save, and sell their home’s power with the Enphase App.

As Supercool readers know, some of the most transformative clean energy breakthroughs happen out of sight—in chips, code, and supply chains.

In Enphase’s case, its sleek user experience is powered by a high-performance software stack, design ingenuity that efficiently mates its software and hardware, and a nimble supply chain.

One Product. Infinite Configurations.

Take its microinverters, the company’s most widely adopted product. Enphase manufactures one piece of standardized hardware. But its software adapts to any market—from California to Germany to India.

“Software is the layer that gives us speed and scale,” Raghu says. “It lets us meet local requirements through code, not factories.”

That means faster deployments. Easier compliance. And a consistent user experience globally.

It’s a new kind of manufacturing strategy built for a digitized, electrified world.

A Smarter, More Flexible Grid—Built From the Edge

The traditional grid expands outward from the center. Enphase builds the grid at its distributed edge.

“Think about mobile phones,” Raghu says. “We used to have one mainframe per building. Now we’ve got a supercomputer in every pocket.”

The same logic applies to energy. Massive power plants, augmented or even replaced by millions of intelligent endpoints, i.e., our homes.

“Imagine neighborhoods sharing energy with each other,” he says. “That’s where we’re heading.”

Manufacturing in America. Deploying Worldwide.

At a time when policymakers are trying to revive American manufacturing, Enphase is already doing it; 85% of its microinverters are produced in Texas and South Carolina.

“It’s about resilience,” Raghu says. “You can’t rely on fragile global supply chains for mission-critical energy tech.”

It’s also strategic, reliable, and close to the customer. Another Silicon Valley maxim put into action: own your value chain.

And for Raghu, it’s a great source of pride. The magnitude of what Enphase has accomplished is profoundly moving to him.

“It makes me incredibly proud that we manufacture right here in America,” Raghu said. “Our technology is built in Texas and South Carolina and shipped to customers around the world. That’s not just good for jobs—it’s good for resilience, for national security, and for the energy transition.

“As an immigrant, to be able to do that, it’s deeply meaningful. It’s not just pride. It’s about contributing to the country that gave us this opportunity.”

Supercool Takeaway

Enphase didn’t wait for the grid to evolve. It started where it could build a business and drive impact, making solar smarter, panel by panel.

Today, it delivers full-stack energy systems that turn homes into renewable energy generators, storage hubs, and active partners to the grid.

And that means:

Precision energy from every panel

One app to manage generation, storage, and use

Standard hardware, customized globally via software

U.S. manufacturing with global reach

That’s how the low-carbon future gets built.

Listen to this podcast episode on Apple, Spotify, YouTube, and all other platforms.

↓

Quote of the week:

We are in a world where the grid is evolving. Where electrification of vehicles, homes—everything is surging. The load on the grid is just increasing, and the grid can’t keep up. So now you're starting to see the need for a distributed grid. That’s what we’ve been working on for 18 years. That future is here. That reality is here. This is not something that’s coming.

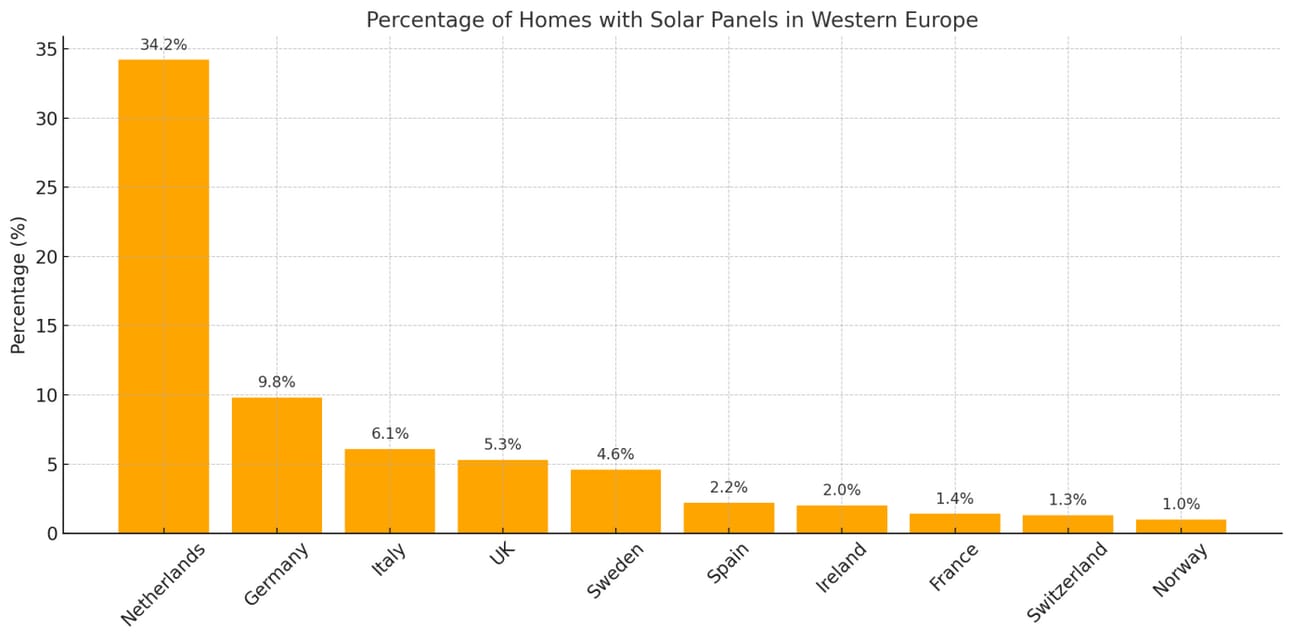

Stat of the Week: 34.2%

That’s the share of homes in the Netherlands powered by solar, the highest residential solar penetration in the world. In the U.S., that number is just 7%. These markets are massive, and the real transformation—homes as grid partners—is just beginning.

↓

The New Industrial Backbone: Clean Energy, Built in the USA

Across solar, wind, and storage, these American companies are manufacturing the hardware enabling the clean energy transition. As with Enphase, they’re creating jobs, managing robust supply chains, and redefining what national power means.

First Solar (NASDAQ: FSLR)

Solar Panels, Made in Ohio, Alabama, and Soon Louisiana

First Solar is the largest American solar manufacturer, producing thin-film modules that don’t rely on Chinese silicon. With three factories in Ohio, a new facility in Alabama, and a fifth underway in Louisiana, the company is on track to exceed 14 GW of domestic production capacity. It’s supporting thousands of jobs and building the solar supply chain America never had.

Nextracker (NASDAQ: NXT)

Precision Solar Orientation, Built with American Steel

Nextracker manufactures the tracking systems that enable utility-scale solar panels to follow the sun, boosting energy output by up to 25%. Its manufacturing partnerships in Texas, Pennsylvania, and Arizona are strengthening U.S. solar infrastructure while reviving domestic steel supply chains.

Tesla (NASDAQ: TSLA)

Home Batteries and Solar Roofs, Built in Nevada and New York

Tesla is turning homes into energy assets—manufacturing batteries and solar systems that give Americans control over how they generate, store, and use power. Its Gigafactory in Nevada produces Powerwalls and Megapacks; its Buffalo, NY facility builds solar roof tiles for distributed, resilient energy.

GE Vernova (NYSE: GEV)

American Wind Power, Engineered for Scale

GE Vernova manufactures wind turbines across the U.S., including for the SunZia project—the largest wind farm in the Western Hemisphere. Its turbines power massive projects and support a skilled American workforce building the future of energy.

↓

Where Supercool Traveled This Week

Three Podcast Appearances:

The Tech Leaders Playbook — Climate Innovation That Actually Sells: No Green Premium Required

The CTO Show — Stop Pitching Tech, Start Selling Outcomes; Josh Dorfman’s Advice for Climate Founders

Speaking of Sustainability — Josh Dorfman of Plantd Shares Insights

↓

Not yet subscribed to Supercool?

Click the button below for weekly updates on real-world climate solutions that cut carbon, boost the bottom line, and improve modern life.

🌐