- Supercool

- Posts

- 🌐 Mass Timber For The Masses: How Sterling Mainstreamed CLT

🌐 Mass Timber For The Masses: How Sterling Mainstreamed CLT

In 2013, I moved to Asheville, North Carolina, to raise our family in one of America’s most beautiful mountain towns.

I had a new venture in mind: a men's sustainable clothing company, and I started visiting mills across the Carolinas. Then I was recruited by the area’s Chamber of Commerce and economic development organization and took a job to build Venture Asheville, the city’s high-growth startup initiative.

A younger me, starting to work on Venture Asheville in 2014.

We created an angel investor network and mentor program for founders. We launched weekly events such as One Million Cups of Coffee and built consistent connectivity among founders, investors, and talent. I loved it.

I met a ton of entrepreneurs and “would-be” entrepreneurs. The doers, the dreamers, and the ones who lived deep in the hills and dressed like Morpheus, straight out of the Matrix, the ones who swore they'd invented limitless energy machines, and the ones building mind software to steer cars with their thoughts. Like the city itself, the job was never dull.

One day, a man came to my office with a plan to build high-rise buildings out of wood. And though this was only just a decade ago, I thought he, too, was disconnected from reality.

Tall buildings made out of wood? Something called Mass Timber? Using an approach called Cross-Laminated Timber or CLT—orienting dimensional lumber at right angles to one another and then gluing them together into panels? Harebrained. Nuts. Waste of time.

It is staggering to witness what's transpired since then.

Mass Timber is on an exponential growth curve. From a handful of buildings in 2011 to over 2,000 projects in 2023—and 24,000 projected by 2034.

In 2016, Albina Yard in Portland, OR, became the first U.S. mass timber office building.

That founder was right about the future. And I was wrong to be dismissive.

The industry’s growth is remarkable. But for most of the past decade, mass timber has remained boutique.

The Runway Problem

Early mass timber buildings were architectural statements. Custom-engineered glulam beams for institutional clients. Libraries destined for magazine covers. Hotels where every detail was hand-specified.

Expensive. Time-consuming. Limited to clients with sustainability budgets willing to pay a green premium.

High-fashion runway work. And like high fashion, it doesn't scale.

Michaela Harms' career arc mirrors the ascendance of mass timber. She grew up in rural Wisconsin surrounded by forests, working on farms and building with alternative techniques—cob, adobe, light clay straw. Then she did something few would dream of: she took a train to the Finnish embassy in Baltimore, passed an entrance exam, and moved to Helsinki to study sustainable building engineering. In Finland, she learned exclusively about wood.

When she returned to the U.S. and entered the mass timber field, she recognized the constraint immediately. "It was this high-end runway thing," she says. "The big sexy institutional projects where it's like, whatever you want, we'll make it happen."

That wasn't going to change construction. That wasn't going to keep sawmills open in the communities where she grew up.

She thought about legendary organic yogurt pioneer Gary Hirshberg taking his beloved Stonyfield Organic to Walmart. Environmental diehards were furious. But Hirshberg brought organic food to more people than anyone before him.

"That was kind of where I was like, okay, we live in capitalism," Michaela says. "How do you use that to propel and scale impact?"

Sterling's Bet: Repeatable Over Bespoke

To go mainstream, mass timber needed to become what Sterling Structural, a 75-year-old lumber company, is now operationalizing: mass timber for the masses.

Repeatable. Modular. Not a premium product but price-competitive with steel and concrete. A drop-in replacement for the building systems contractors already use.

In 2015, Sterling started manufacturing Cross-Laminated Timber. Today, they're America's largest CLT manufacturer. One panel every 65 seconds. Two facilities. 100% domestic lumber. One million panels produced. Michaela is the company’s Vice President for Mass Timber.

To reach scale, Sterling built around existing sawmill infrastructure. Standard lumber dimensions. Panels that slot into the same systems as steel decking or concrete slabs. Same format. Wood instead.

"If you can open up your eyes and say what exists today, build a product off of it, and then design to it," Michaela says, "you make construction faster, you make the price right."

No exotic engineering grades. No special sourcing. No green premium. Just repeatable, accessible, price-competitive mass timber.

The Amazon Test

In 2023, engineers from KPFF in Seattle came to Sterling with a challenge. Amazon wanted a fulfillment center in Elkhart, Indiana, that could hit budget, go up fast, and integrate cutting-edge sustainability.

Early estimates weren't working. The custom glulam beams kept getting larger and more expensive. The project was at risk of cutting mass timber entirely.

Sterling's answer: go hybrid. Deploy CLT strategically where it made the most sense—floors and roofs. Use steel beams where steel makes sense.

They designed 16-foot CLT panels to match 16-foot steel bays. Sterling delivered 1,100 prefabricated panels just-in-time from their Illinois plant, 100 miles away. The building went up in weeks.

Sterling’s mass timber panels inside Amazon’s Elkhart distribution center.

Amazon highlighted it as part of 40+ sustainability strategies. But the project worked because it competed on economics, not climate messaging.

The Forest Market Is Collapsing

Sterling sources exclusively from U.S. sawmills, a business model tied to regional economies.

The past few years have seen sawmills face extreme financial pressure and close, forcing the industry to contract.

When sawmills close, private landowners lose the financial incentive to manage forests. Legacy land held for generations gets sold off. Overstocked stands fuel wildfire risk.

"Without markets for timber," Michaela says, "that's what causes deforestation, not utilization, but the collapse of these markets."

According to Michaela, North American forests regrow the equivalent volume Sterling uses for one million panels in 66 hours. The constraint isn't supply. It's the demand for lumber products that keeps sawmills open.

"I want to get as much lumber into as many buildings to keep sawmills open, to keep loggers working," she says. "That's the community I grew up with."

From Runway to Target

Today, customers come to Sterling because their CLT panels install fast, deliver just-in-time, compete on price, and come from a reliable domestic supply chain.

That shift—from sustainability pitch to logistics advantage—is how mass timber goes mainstream.

Sterling isn't chasing architectural magazines. They're chasing strip malls, warehouses, and military hotels. The Candlewood Suites at Fort Bragg is all mass timber but covered in drywall.

The Candewood Suites at Fort Bragg, but with Sterling CLT panels.

"If you can show it, awesome," Michaela says. "If you can't, it's still there."

Supercool Takeaway

Sterling Structural is proving that climate solutions scale fastest when they compete on economics—not sustainability messaging. By making CLT standardized, modular, and price-competitive, Sterling is moving mass timber from boutique to ubiquitous.

Operator Takeaways

Build for what exists, not what's ideal. Sterling designed around existing sawmill output—making adoption friction-free for contractors and developers.

Sell the business case, not the mission. When economics close the deal, climate impact follows. Sustainability becomes the benefit, not the barrier.

Strategic beats total replacement. Hybrid approaches scale faster than all-or-nothing. Deploy new materials where they win, not everywhere.

This Week’s Podcast Episode

Mass Timber For The Masses: How Sterling Mainstreamed CLT

🎙️ Listen on Apple, Spotify, YouTube, and all other platforms.

↓

Stat of the Week: 25.6 to 39

The amount of gigatons of carbon emissions that could be reduced by switching 30%-60% of new urban buildings to mass timber construction, according to researchers at Yale University—equivalent to nearly all global energy-related emissions in 2024.

Still, others say, not say fast. Researchers at the World Resources Institute (WRI) challenge whether the entire impact of cutting down trees in forests for commercial-scale building construction is fully accounted for in estimates of mass timber’s benefits.

Our Take: We’re not experts, but we’re fans. Further, renowned architects and experts who have been on Supercool, like Eric Corey Freed, now Sustainability Director at Cannon Design, are supporters for multiple reasons:

Reduced carbon impact

Increased connection between the built environment and the natural world

More vibrant, healthy spaces

Less-energy intensive construction process

Quote of the Week:

"I can go build a couple of Adobe buildings out in the middle of the desert and live there all alone and have very little impact, but I want to make a bigger impact. I want to make a bigger impact doing little impact."

↓

🌐 The Climate Adoption Playbook

Climate innovation is half the battle. The other half? Getting customers to adopt it.

The good news is that successful climate companies have figured it out. The great news is they all do the same thing.

They pull from a set of five adoption levers. Sometimes they use just one. Often, they combine them to create even stronger value propositions. But, no matter the market or industry, their entire playbook consists of these levers:

🧩 Friction Removal (Make it easier)

✅ De-Risked Adoption (Make it credible)

🎨 Lifestyle Upgrade (Make it aspirational)

💳 Financing as the Unlock (Make it affordable)

♻️ Circular Advantage (Make it profitable)

The Climate Adoption Playbook teaches you how to use these levers too. It’s the first course built on real-world case studies of companies that have gone from pilots to commercial scale to meaningful market share, now shaping the low-carbon future.

To make it easier to dive in during the holidays—and as you gear up for the year ahead—we’re offering a special holiday price.

Now through January 15, 2026, the course is discounted from $499 to $199, with ongoing access and updates for the next year included.

↓

Part of mass timber’s appeal is its versatility; the same materials and systems can support everything from housing and workplaces to campuses and civic institutions. Here are five U.S. projects completed in the past 12 months that reflect that breadth.

University of Arkansas, Fay Jones School of Architecture and Design

The Anthony Timberlands Center for Design & Materials Innovation at the University of Arkansas is an academic hub dedicated to timber design, research, and fabrication using mass timber and other materials. The project incorporates biophilic design, daylighting strategies, and ecological landscaping that connect the campus to the Ozark landscape.

Portland, OR — Affordable Housing

Timberview is an 8-story affordable housing apartment building in Portland, built with mass timber. It features 105 subsidized units and a ground-floor food hall, and community-focused spaces.

Bentonville, AK — Walmart Headquarters

The new Walmart headquarters is a massive sprawling 350-acre campus featuring mass timber office buildings. All buildings are four to five stories tall to reinforce a human-centric scale.

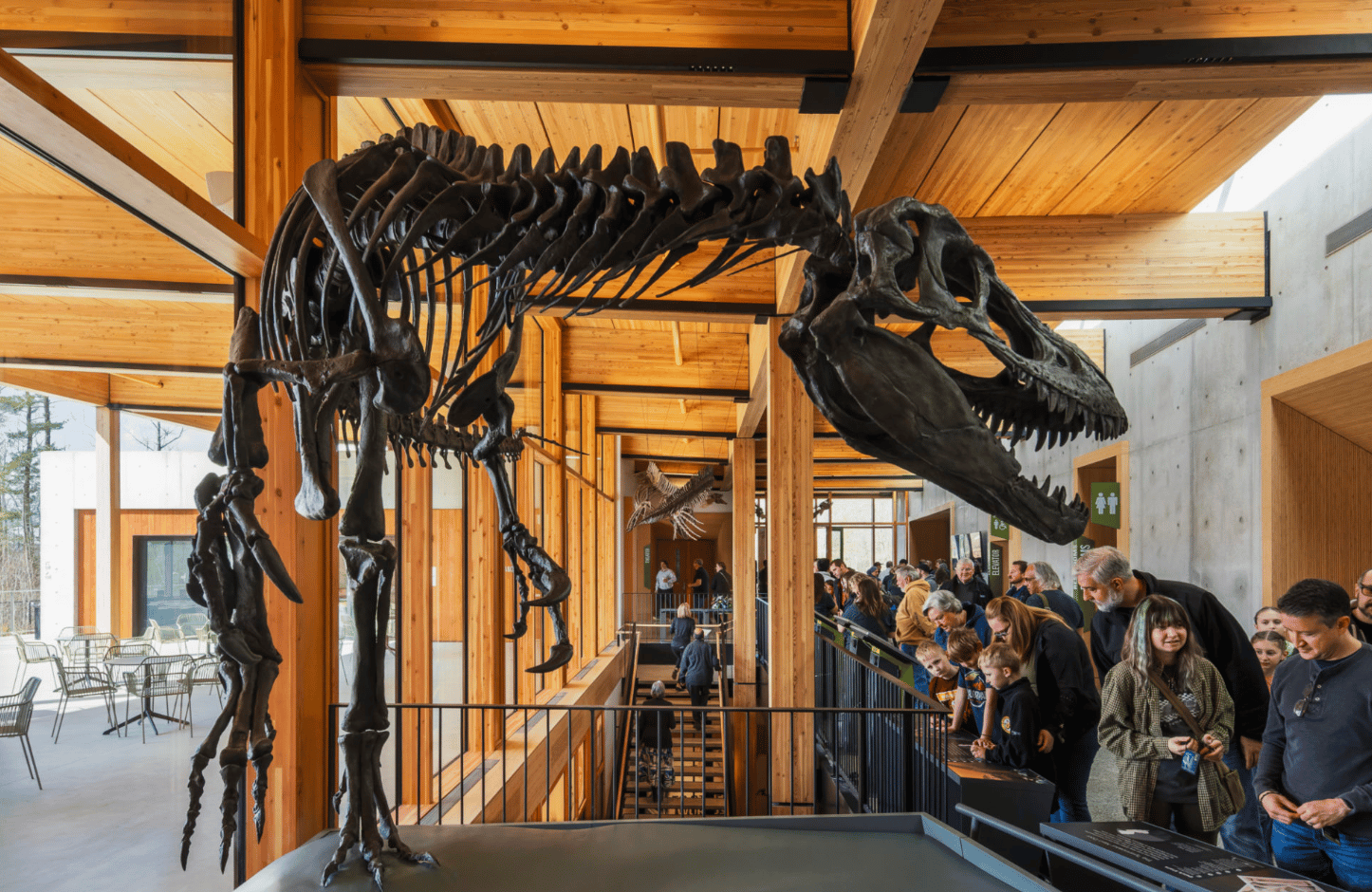

Rowan University in New Jersey, Edelman Fossil Park & Museum

The Edelman Fossil Park & Museum at Rowan University is one of the largest public net-zero carbon-emissions buildings in New Jersey. The post-and-beam framework incorporates mass timber products, including glulam and CLT panels.

San Diego, CA - Mixed Use Development

Niima is a contemporary 5-story mixed-use development featuring 55 loft-like apartments and two ground-floor restaurant spaces. It was constructed using CLT, allowing the exposed wood to create vibrant, natural living experiences.

↓

PODCAST

Streetsblog USA: Five ‘Supercool’ Founders to Watch in 2026 with Josh Dorfman

↓

Interested in Advertising with Supercool?

Connect with future-forward decision-makers seeking next-gen climate innovations. Reach out to discuss how Supercool’s platform can help. Just hit reply to this email.

↓

Not yet subscribed to Supercool?

Click the button below for weekly updates on real-world climate solutions that cut carbon, boost the bottom line, and improve modern life.

🌐