- Supercool

- Posts

- 🌐 Mining Solar Panels to Build New Ones

🌐 Mining Solar Panels to Build New Ones

SOLARCYCLE turns the solar industry’s waste stream into its next supply chain—making clean energy truly renewable.

Adoption Archetype: ♻️ Circular Advantage — Make it profitable.

The clean-energy transition is already vast beyond imagination. Across deserts, farmland, and rooftops, solar fields now stretch the size of cities.

The solar industry’s rise has no historical parallel. It took coal fifty years to overtake wood. It took oil another fifty to overtake coal.

Solar surpassed both in less than twenty years—now the cheapest power on Earth and quickest to deploy.

Last year, over a billion solar panels were installed worldwide. Billions more are coming. In the U.S., 800 million panels are already in place—two for every American.

Politics can slow it down, but the physics and economics have already won. Solar’s ascendance is inevitable.

Yet, Jesse Simons, co-founder & Chief Strategy Officer at SOLARCYCLE, sees what the industry has long refused to face: the greatest threat to solar’s future is its own success.

The Realization

Jesse spent two decades at the Sierra Club, driving the retirement of coal plants and the expansion of clean energy. But the faster solar grew, the clearer its limit became.

“You can build it once,” he told me, “but you can’t throw it all away and rebuild it again. There isn’t enough silver and copper to do that twice.”

Solar already consumes 20 percent of the world’s silver. In the U.S., meeting projected demand would require more than the nation’s total aluminum output.

“It’s clean energy,” he said, “but it’s not clean energy if you’re destroying the planet to get all the minerals—and then throwing the panels in a landfill.”

That realization pushed Simons and his co-founder, Suvi Sharma, to act. Sharma, who had built solar manufacturing powerhouses Nextracker and Solaria, saw the same wall ahead.

Together, they launched SOLARCYCLE in 2022 to build the industry’s circular solution before the shortage hits.

They built it from the inside out: logistics lead from Amazon, manufacturing veterans from SunPower and First Solar, and Dr. Pablo Díaz, SOLARCYCLE’s third co-founder and the world’s leading solar-recycling scientist, whose research turned a lab experiment into an industry blueprint.

“We were built by the solar industry for the solar industry,” Jesse said. “We weren’t outsiders trying to sell sustainability. We were peers who understood the pain points.”

⚙️ A billion panels were installed last year. Hundreds of millions will soon need recycling.

Here’s SOLARCYCLE’s playbook for building solar’s critical new supply chain.

1. Start with Credibility

Be built by the industry you serve.

Founders and early hires came straight from solar manufacturing, logistics, and EPC (Engineering, Procurement, and Construction) firms. That insider DNA gave SOLARCYCLE instant access to the biggest asset owners—AES, NextEra, Engie, Brookfield, and Sunrun—because the team knew how those companies buy, build, and measure risk.

2. Solve for Legitimacy

Make recycling the ticket to project approval.

In zoning hearings, developers faced one question: What happens to all these panels at the end of life?

“When a developer can walk in with a recycling agreement from SOLARCYCLE,” Simons said, “it changes the conversation. It takes the fear off the table, and the project moves forward.”

Recycling stopped being a gesture. It became the proof that kept projects approved and profitable.

3. Win on Reverse Logistics

Before the factory, master the road.

Before building a plant, they built a logistics network. “Getting logistics wrong,” Simons said, “is the difference between this business succeeding or failing. The spreadsheet always wins.”

Veterans from Amazon and NextTracker engineered reusable packaging, optimized truckloads, and sited hubs near hail-prone solar corridors.

By 2025, SOLARCYCLE’s network will be within a day’s drive of 90 percent of U.S. solar capacity. Every mile, every pallet—engineered for cost parity.

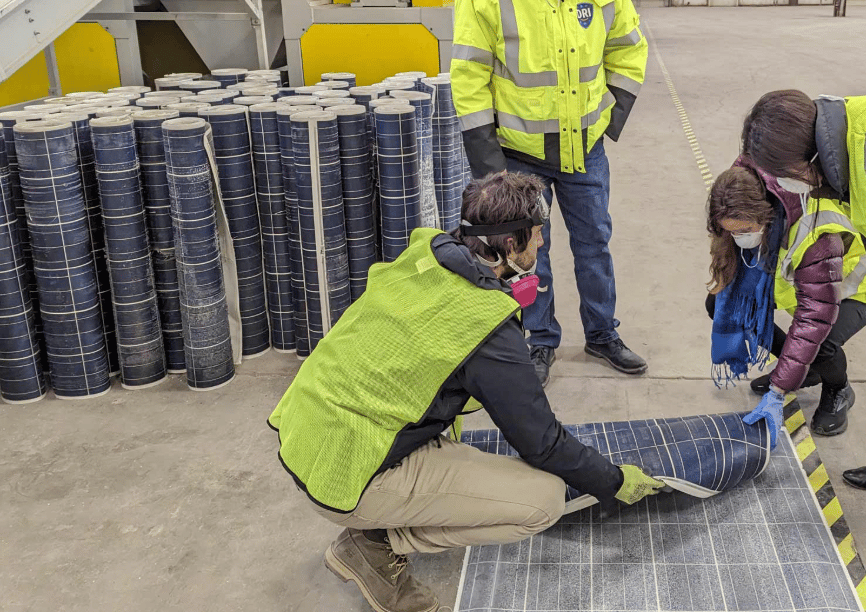

4. Think of It as Manufacturing, Not Recycling

Recover value, not just materials.

Inside the plant, automation rules. Forklifts unload pallets straight into robotic lines. Junction boxes come off first for copper and plastics, followed by aluminum frames that are stripped in seconds.

“We’ve built multiple generations of tools to get that frame off faster,” Jesse said.

What remains is the “glassy laminate”—a thin, silver-laced circuit of copper and silicon that holds roughly 60 percent of a panel’s recoverable value.

That’s where the real economics are encased. SOLARCYCLE’s process separates the layers with heat, vibration, and precision milling to reclaim ultra-clean glass, high-purity copper wire, silicon wafers, and the silver paste that drives every solar cell.

Silver is the smallest component by weight but the highest by value—critical for conductivity and costly to replace. “The cleaner we get it,” Jesse said, “the higher the resale value. It’s what makes this a manufacturing business, not a waste business.”

Because new panels generate nearly three times more power from the same materials, every old panel becomes the raw material for three new ones.

5. Drive Toward Landfill Parity

Make recycling as cheap as disposal.

In the 2010s, “grid parity” made solar inevitable. Now, Jesse says, “Landfill parity will do the same for recycling.”

SOLARCYCLE isn’t there yet—but it’s closing in fast. Automation, optimized routes, and high-value offtake deals are shrinking the gap every month.

Reverse logistics improvements have already driven transport costs down dramatically.

Recovered materials—especially silver, copper, and glass—offset more of the processing costs with each generation of refinement.

“The goal,” Jesse said, “is to get to the point where recycling isn’t much more expensive than landfilling. And we’re getting closer all the time.”

The economics are catching up to the physics.

6. Create Pull Through in the Supply Chain

Let circularity cascade from the top.

Corporate buyers like Microsoft, Amazon, and Meta now require recycling plans in their power purchase contracts. Local zoning boards increasingly do too.

“It’s not a green premium anymore,” Jesse said. “It’s a license to operate.”

Developers need it to secure permits. Asset owners need it to win deals. Recycling has become the price of participation.

7. Build for the Coming Scale Shock

Treat early volumes as training for the billion-panel future.

SOLARCYCLE recycled half a million panels last year. This year, it’s on track for a million. By the 2030s, hundreds of millions will retire each year.

“We’re creating the market now,” Jesse said, “so when the surge hits, we’re ready.”

And because modern panels produce three times more power from the same materials, circularity compounds the return.

“Once you’ve installed those terawatts,” he said, “you can just keep reusing the same materials forever.”

🌐 Supercool Takeaway

SOLARCYCLE makes clean energy self-sustaining—turning end-of-life panels into new panel inputs and waste into margin. That’s how the future remains bright.

Operator Takeaways:

Start where others stop. Build in the part of the value chain everyone else ignores.

Make logistics strategic. The trucks, packaging, and plant locations are the economics.

Solve for scarcity. Materials drive the market—control recovery, and you control growth.

This Week’s Podcast Episode

Mining Solar Panels to Build New Ones

🎙️ Listen on Apple, Spotify, YouTube, and all other platforms.

↓

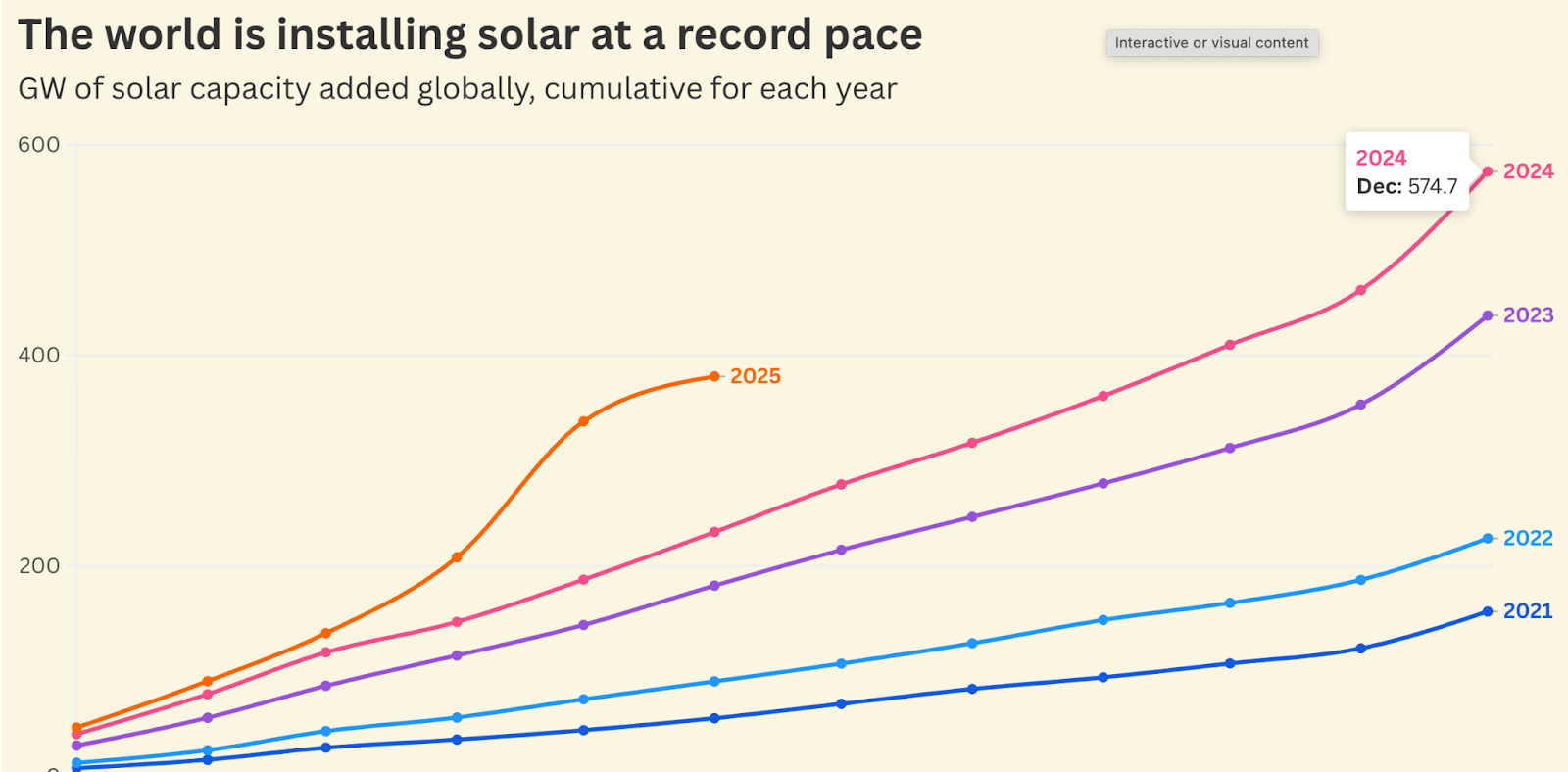

Stat of the Week: 1.725 Billion

That’s roughly how many solar panels were installed worldwide in 2024 — about 3 million panels per gigawatt across 575 gigawatts of new capacity.

In 2025, global installations are on pace to climb even higher.

Source: Canary Media

Quote of the Week:

There’s no solving the climate problem without solving the circularity problem.

↓

Sneak Preview

The Climate Adoption Playbook

Innovation is half the battle. Adoption determines who succeeds.

We’ve spent the past year going in-depth with over 50 of the world’s leading climate companies to understand how they rapidly win customers, grow revenue, and capture markets.

Across industries and business stages, the same pattern repeats.

The companies that scale operate from the same playbook.

We’ve distilled it into five adoption levers every climate and sustainability operator can use to accelerate growth.

The new course drops tomorrow. Catch a sneak peek here.

↓

Clean Energy’s Next Act Is Circular

The clean-energy boom built a global industry. Now that industry is learning how to rebuild itself. Across solar, wind, and batteries, companies are reclaiming the metals, glass, and composites of the first generation and turning them into new supply—making renewable power truly renewable.

Redwood Materials is closing the loop on batteries at industrial scale. Founded by Tesla co-founder JB Straubel, it recovers copper, nickel, and lithium from used EV and consumer batteries to supply Panasonic, Toyota, and Ford. Today, its Nevada campus processes enough material for roughly 400,000 electric vehicles each year.

First Solar integrates recycling directly into production. The company’s closed-loop facilities recover more than 90 percent of semiconductor material from retired panels and feed it straight into new ones. As the largest U.S. solar manufacturer, producing over 16 gigawatts of panels annually, First Solar has already recycled tens of millions of modules.

Vestas is rewriting what’s possible for wind. Its new chemical process dissolves epoxy resin in turbine blades and recovers the fibers for reuse, eliminating one of renewable energy’s hardest waste problems. The world’s largest turbine maker, with more than 170 gigawatts installed worldwide, is building circular design into the next generation of blades.

Siemens Gamesa has already taken that step offshore. Its RecyclableBlade technology, installed on North Sea wind farms operated by Ørsted, separates composite materials with low-energy chemistry and returns them to production—showing how full recovery can work at industrial scale.

RecyclableBlades leaving land for an offshore wind development.

B2U Storage Solutions gives EV batteries a second life on the grid. At its Lancaster, California facility, more than a thousand repurposed Nissan Leaf packs store energy for peak demand—helped by diagnostic technology from companies like Rejoule that make reuse possible at scale. The 25-megawatt-hour system is the largest second-life battery project in North America and a commercial proof that reuse can add capacity faster than recycling.

Together, these companies are extending the life of the materials that power clean energy—turning the transition into a self-renewing industry.

↓

Where Supercool traveled this week:

Ramp NYC

Our friends at Bloxspring invited me to speak at Ramp NYC, the conference that brings together marketing, communications, and brand leaders in proptech and security.

I spoke about the playbook we’ve used at Plantd to drive market adoption, and the insights we share through Supercool, talking with successful climate tech founders, CEOs, and execs about how they do the same.

That now culminates in the upcoming launch of our new course for operators: Supercool’s Climate Adoption Playbook.

↓

Interested in Advertising with Supercool?

Connect with future-forward decision-makers seeking next-gen climate innovations. Reach out to discuss how Supercool’s platform can help. Just hit reply to this email.

↓

Not yet subscribed to Supercool?

Click the button below for weekly updates on real-world climate solutions that cut carbon, boost the bottom line, and improve modern life.

🌐