- Supercool

- Posts

- 🌐 Simple, Unstoppable: Rondo Energy is Solving Industrial Heat with Bricks

🌐 Simple, Unstoppable: Rondo Energy is Solving Industrial Heat with Bricks

Inside Rondo's radically simple—and wildly scalable—clean industrial heat platform.

Half the fuel we burn in the world isn’t for transportation or electricity. It’s for heat.

That single fact unlocks a staggering realization: one of the largest sources of global emissions—industrial heat—has been hiding in plain sight. And it’s not just big. It’s hard. Hard to electrify. Hard to retrofit. Hard to decarbonize without dismantling the very factories the world runs on.

Which is why what Rondo Energy is doing is so surprising.

Their solution doesn’t require new factories or futuristic chemistry. It’s based on clay bricks and toaster wire—scaled and engineered to store clean electricity as high-temperature heat. And it works with the equipment factories already use.

It’s one of the simplest, cheapest, and most scalable decarbonization technologies underway—and it’s aimed directly at the industrial sector’s biggest emissions challenge.

In this week’s episode of Supercool, we talk with John O’Donnell, Rondo’s co-founder and Chief Innovation Officer, about how this technology came to be, why it’s working now, and how it’s poised to drive the next wave of global decarbonization.

The Hard-Won Wisdom Behind Rondo’s Strategy

You don’t build infrastructure-scale climate tech without scars.

Before founding Rondo, John led five startups—including one that built over half the world’s solar thermal heat capacity. The technology worked. But it didn’t reach infrastructure-scale. The finance community wasn’t ready.

“Technologies aren’t relevant to solving climate unless they’re built at billion-dollar scale,” he says. “There are no gigatons without gigabucks.”

That experience—building global projects, failing to raise project-scale capital, learning what investors need to say yes—is what shaped Rondo’s DNA.

From day one, the company was engineered not just to work in a lab, but to win in the field, at scale, under real financial scrutiny. That means proven supply chains, modular design, drop-in compatibility with existing industrial systems, and project development timelines that institutional investors can underwrite.

“If a technology is going to go to scale quickly, it has to be profitable for everyone in its ecosystem,” John explains. “The user, the maker, the financer—it has to work for all of them.”

Why Industrial Heat Is the Next Frontier

Industrial heat is used to produce essential materials—steel, cement, chemicals, food, and fuel. Globally, it represents around 25% of all fuel consumption and a huge slice of carbon emissions.

Unlike EVs or clean power, industrial processes aren’t easy to electrify. Most factories are optimized around steam or high-temperature heat, not electrons. That’s why companies often turn to natural gas—even when solar or wind power is abundant.

But thanks to the explosive growth of wind and solar energy, electricity is becoming too cheap to ignore. In many markets, solar and wind now produce excess energy during the day—at times so much that prices go negative.

What the grid needs is flexible demand. What industry needs is round-the-clock heat.

Rondo delivers on both fronts.

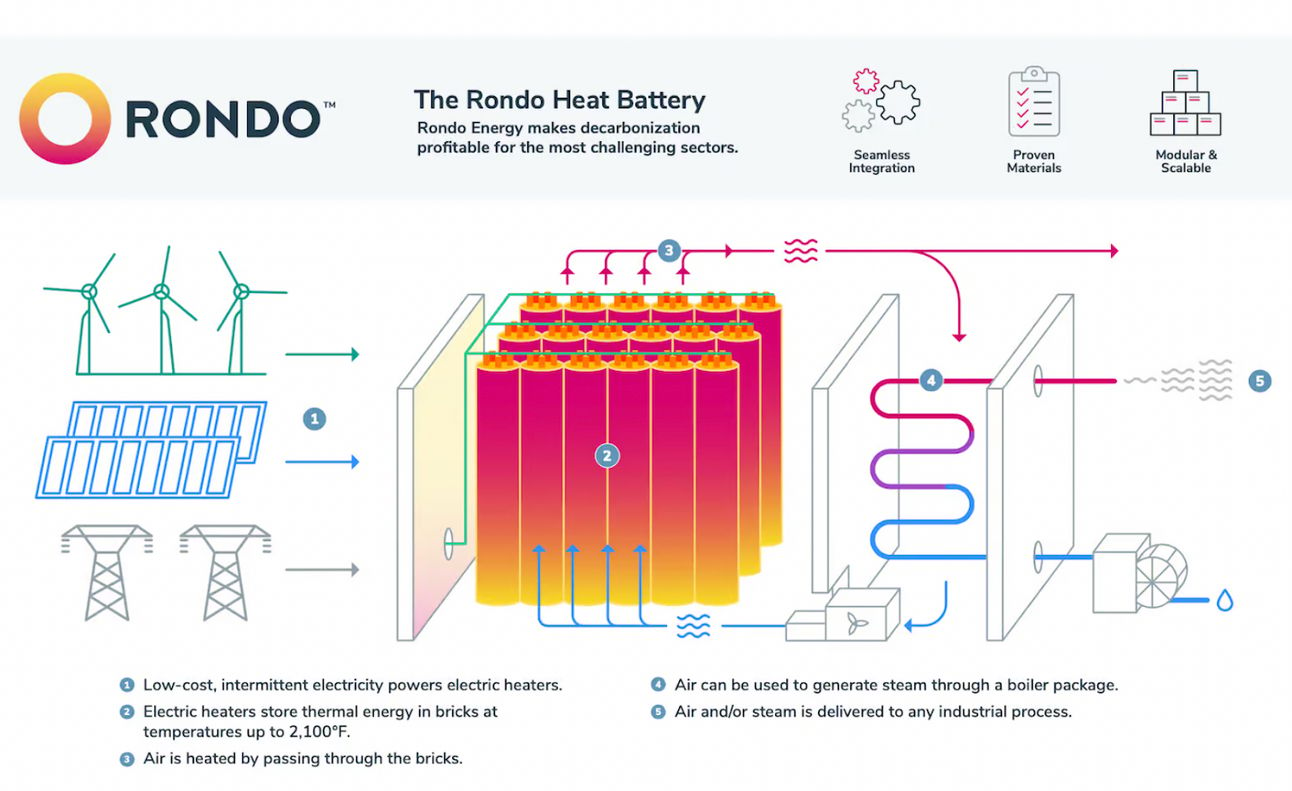

Inside the Rondo Heat Battery

At the heart of Rondo’s system is a simple idea: store electricity as heat, and release it as high-temperature steam or air when needed. The heat is stored in bricks—yes, actual clay bricks— using resistive elements like you’d find in a toaster or hairdryer. The system then delivers that heat as clean, continuous air to existing steam boilers or process heaters.

There’s no combustion. No flammable materials. No rare earth minerals.

Rondo’s heat bricks made of clay.

Because it’s modular and built with off-the-shelf components, it scales fast and lasts 50 to 100 years.

“We’re storing heat in brick,” John says. “The same material the steel industry has been using since the 1850s. Our resistive heater? It’s literally the same material that’s in your toaster or your hairdryer.”

This is grid-scale energy storage for industry at a fraction of the cost and complexity of electrochemical batteries.

It’s Already Working

Rondo Inside: The company’s heat bricks are stored within a container-like structure. The heat is then delivered directly into the industrial infrastructure on site.

Rondo is already active in five countries. It’s delivering clean heat at a biofuels facility in California. It’s working with a cement plant in Thailand. It’s replacing gas in Germany—right next to an LNG import terminal built during the Russian energy crisis.

It’s even being piloted by Diageo, the global beverage giant, to decarbonize whiskey production in Kentucky.

“We’re already making alcohol today in California—but it’s fuel alcohol. In Kentucky, it’s the good stuff.”

And it’s not just small test beds. In some cases, Rondo could help major industrial players meet 80% of their 2035 climate goals by retrofitting just a few facilities.

“If we prove the technology in one facility,” John says, “there’s a global growth path.”

Built for the Moment

What makes Rondo so compelling isn’t just the tech. It’s that this kind of system is now economically obvious.

Ten years ago, using electricity to make industrial heat was economically unthinkable. Today, it’s inevitable. Renewable electricity is now the cheapest energy on Earth—and often effectively free in markets with high solar or wind penetration. What used to be waste is now an asset. What used to be a liability—intermittency—is now an opportunity.

“Jenny Chase at Bloomberg NEF says that by 2030, on a sunny day in developed countries, electricity is free,” John notes. “That’s a world of wealth and abundance. The question is: how do we put it to work?”

This is the moment Rondo was built for.

The Supercool Takeaway

Rondo Energy isn’t chasing hype. It’s solving a problem that’s massive, measurable, and right in front of us.

By turning surplus solar and wind energy into reliable industrial heat, Rondo unlocks a new phase of decarbonization—one that doesn’t ask factories to reinvent themselves or bet on bleeding-edge science.

This is the kind of climate solution we need more of:

Proven.

Profitable.

Ready for global deployment.

And most of all, it reminds us that the low-carbon future won’t always be shiny. Sometimes it’s made of brick.

🎧 Listen to the episode now to hear how Rondo Energy is repowering industry, attracting infrastructure capital, and building one of the most scalable decarbonization platforms on Earth.

📨 Know someone in heavy industry, energy, or climate finance? Forward this episode their way.

Listen to this podcast episode on Apple, Spotify, YouTube, and all other platforms.

↓

Stat of the Week: 10%

The amount of global greenhouse gas emissions generated by industrial heat. That’s more than cars (6%) and planes (2%) combined. Solutions from companies like Rondo are mission critical and have drawn a group of global venture capital and corporate backers, including:

Breakthrough Energy Ventures, Energy Impact Partners, SCG (Siam Cement Group), Microsoft's Climate Innovation Fund, Rio Tinto, Aramco Ventures, The Goldman Sachs Group, H&M CO:LAB, and the European Investment Bank.

Quote of the Week:

“When you heat this brick to 1000°C and cool it back down, it stores about as much energy per pound as a lithium-ion battery—but it lasts 50 to 100 years and costs single-digit dollars per kilowatt hour.”

– John O’Donnell, Co-founder and Chief Innovation Officer at Rondo Energy

↓

Where Industry Is Heading

In a world of rising tariffs and shifting trade dynamics, supply chains are being reconfigured—but not severed. From Vietnam to Denmark to post-war Ukraine, a new kind of industrial park is taking shape—where smokestacks are out, and solar panels, heat batteries, and circular systems are in.

Vietnam: Powered by Rooftop Solar

Sumitomo Corporation is turning rooftops into energy infrastructure in Vietnam. At its Thang Long Industrial Park, over 10 megawatts of solar have been installed to help tenant factories meet the emissions standards of overseas buyers. It’s a clean energy supply chain enablement—and a model Sumitomo is already expanding to Bangladesh.

Denmark: Clean Heat, On-Site

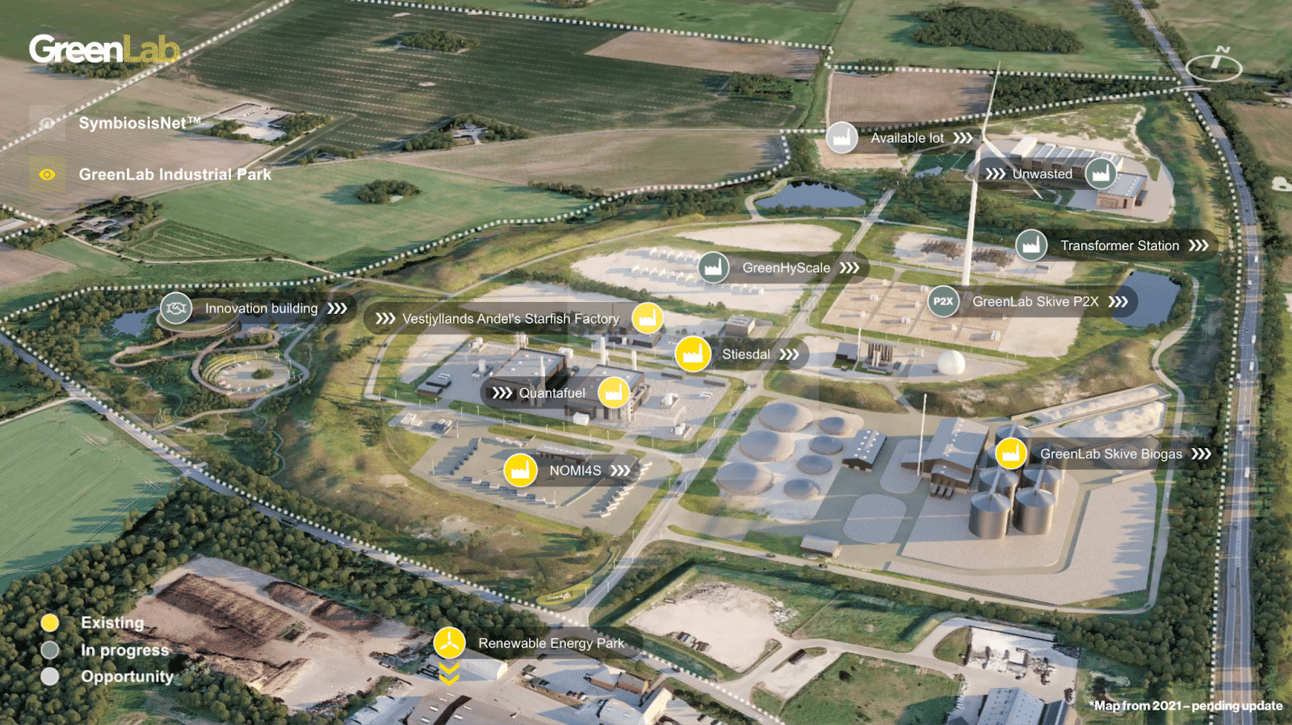

At GreenLab, a Danish industrial park powered by wind and solar, Rondo Energy is installing a 100 MWh heat battery to deliver round-the-clock industrial heat to the park’s tenants including manufacturers of green hydrogen, sustainable fish protein, and construction materials. The park’s companies also share byproducts and materials—creating circular value streams and reducing carbon without long-distance energy transmission.

Ukraine: Rebuilding With Green Industry

As Ukraine prepares for what may become the largest reconstruction project of the modern era, sustainable manufacturing is moving to the forefront. Led by the Ministry of the Economy, the country is planning a new wave of eco-industrial parks—designed for circularity, powered by renewables, and integrated into the European economy. Last week, it hosted the second annual Eco-Industrial Parks Forum.

↓

Where Supercool Traveled This Week

This past week, I joined a trio of sustainability podcasts to talk about Supercool’s mission—covering the low-carbon economy through the lens of what’s already working.

🎙 Social Entrepreneurship & Sustainability Show

Carbon-Negative Innovation with Josh Dorfman

🎙 Climate 4 Fun

Meet the Laziest (Yet Supercool) Environmentalist Ever

🎙 Flanigan’s Eco-Logic

Josh Dorfman on Sustainable Building Materials

↓

Not yet subscribed to Supercool?

Click the button below for weekly updates on real-world climate solutions that cut carbon, boost the bottom line, and improve modern life.

🌐