- Supercool

- Posts

- 🌐 Stop Sorting: How UBQ Materials Uses 100% Of Your Trash

🌐 Stop Sorting: How UBQ Materials Uses 100% Of Your Trash

I once built a media company around a basic idea: I despised recycling.

Separating trash felt like punishment. Washing tiny plastic soy sauce cups. Forgetting my pizza box was contaminated the second that grease touched the cardboard. Never knowing whether styrofoam is recyclable (is it?).

That frustration turned into a primetime TV series on Sundance Channel and a daily radio show on SiriusXM called The Lazy Environmentalist—my quest for green solutions that fit how humans actually behave, not how we wish they would.

This week, I spoke with Albert Douer, CEO of UBQ Materials, who has built a company on the same philosophy. His insight: separating recyclables is the recycling bottleneck, not the solution.

UBQ doesn't want you to sort your garbage. They want your entire trash bag. All of it.

The chicken bones. The greasy pizza box. The empty dish soap bottle. The dirty diapers—which, as Albert proudly told me, "we love them dirty."

Every single item gets used—100% utilization. Nothing goes to the landfill.

We Built Infrastructure for a World That Doesn't Exist

For 30 years, we've invested in sorting systems built on fantasy:

Consumers will separate trash perfectly

Contamination can be eliminated

Municipalities will process everything correctly

Recycling economics can support robust infrastructure

"People thought we could recycle 100% of what we throw away," Albert said. "Never gonna happen. It's very easy to recycle the first 10, 20% of what we throw away. Very hard from then on."

Take the pizza box conundrum. You eye the recycling bin, box in hand, wondering if the grease disqualifies it. Most people guess wrong. That single contaminated box can ruin an entire batch of otherwise recyclable paper.

Scale that confusion across every household item—mixed plastics that require different equipment, food residue inside containers, multi-layer toy packaging—and it’s clear why the system fails.

Even when recycling works, conventional plastics degrade over time. Every cycle cuts the polymer chains. You get 1 to 2 uses before the material is worthless.

UBQ started from a different premise: what if contamination doesn't matter?

From Waste to Material in One Step

Albert spent 15 years in the plastics industry before founding UBQ. He understood recycling’s challenges. When Israeli engineers showed him patents for a process that could turn entire garbage bags into thermoplastic material, the initial plan called for three years of R&D to reach commercialization. Albert invested and joined as Chairman and CEO.

Ten years later, UBQ began shipping products.

"If this had been in the hands of a normal venture capitalist, this project would've failed," Albert said. "No one would've stuck with it."

For Albert, there was no choice. The breakthrough was too significant, and the stakes were too high. When introducing a new industrial material into the production processes of the largest companies on earth, there is no margin for error. It has to be right the first time.

Today, UBQ's 80,000-ton facility in the Netherlands combines cutting-edge product and manufacturing innovation. Household waste is processed with zero water, zero emissions, and zero byproducts. Heat pumps recycle energy throughout the plant. Everything that enters becomes product.

UBQ’s manufacturing facility in the Netherlands

The result: a bio-based (80% organic content) and carbon-negative material (removing 11.7 kg of CO2 equivalent per kilogram of material produced).

Plus, it costs the same as virgin plastic. And since UBQ materials are not traditional polymers, they don't degrade when recycled.

UBQ™, the first thermoplastic made from 100% unsorted waste, including all organics.

"We have recycled pure UBQ over 10 times," Albert said. "You cannot do that with plastic without adding anything else."

Breaking The Sacred Rule of Plastics

Traditional plastics follow one ironclad law: never mix polymers.

Want to switch from polystyrene cups to recycled PET? You need new extruders, thermoformers, tooling, and grinders. Hundreds of millions in capital investment. Few companies are willing and able to commit those resources.

So UBQ upends the rules.

The material can be used alone with 100% purity or blended with polypropylene, polyethylene, PVC, or polystyrene in existing equipment, with zero additional capital investment.

"We can literally have someone try UBQ in the morning and ship product with UBQ in the afternoon," Albert said.

Albert calls it "the lazy man's material." This is how climate adoption happens—not by asking manufacturers to rebuild factories, but by fitting seamlessly into how they operate. Because even when everything aligns, onboarding customers still takes time.

Mercedes Said Yes

UBQ spent years working with Mercedes-Benz to incorporate its material into car interiors through an exhaustive due diligence process.

"Can you imagine the amount of technical inspection they asked for before a part can go into a Mercedes car?" Albert said, "For me, that is like getting a seal of approval from God."

Once Mercedes signs off, every other manufacturer starts paying attention. McDonald's uses UBQ. So do major construction material suppliers across Europe. The technical barriers are gone. The performance is proven. The economics work.

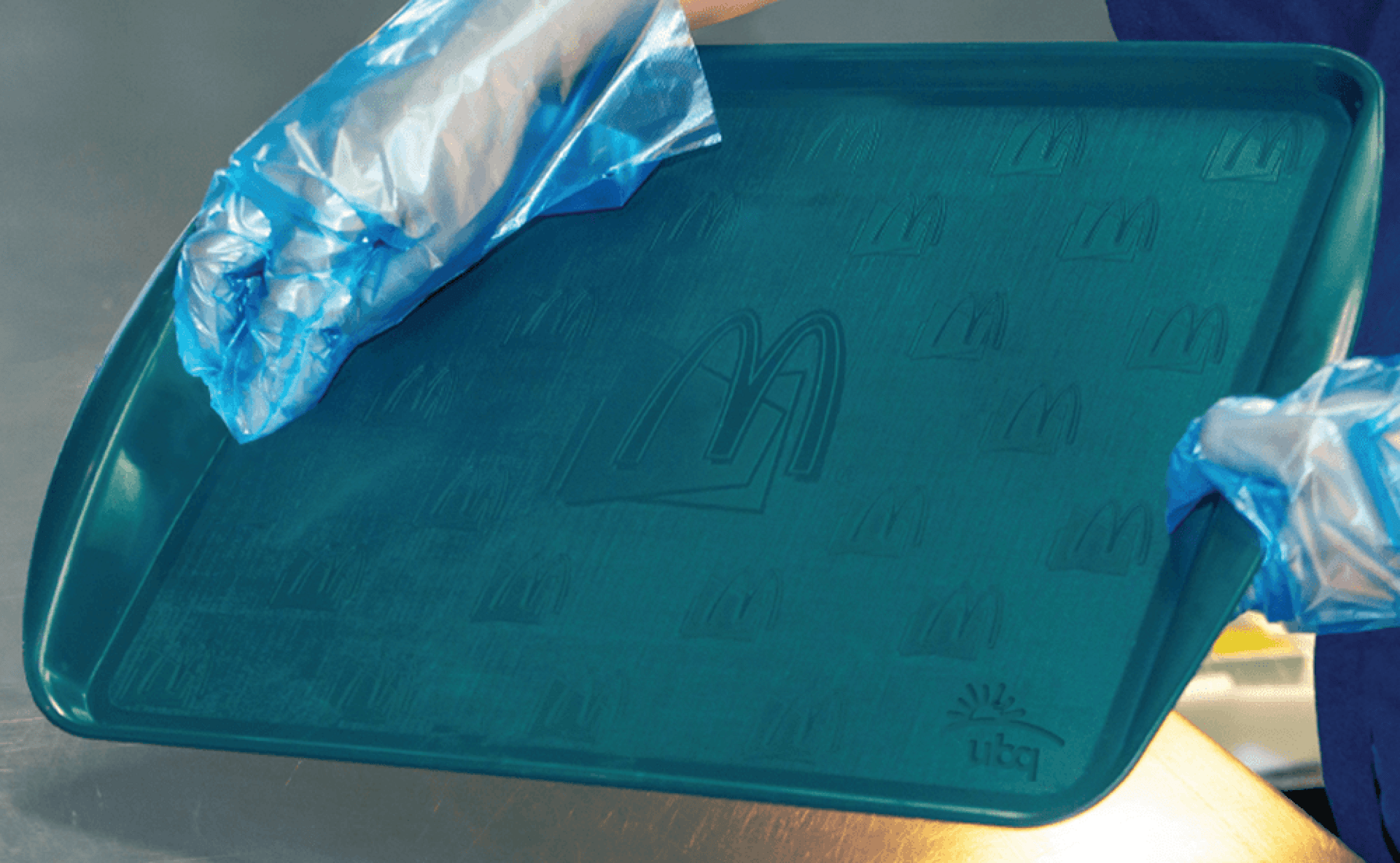

A McDonald’s tray made from UBQ materials.

"There are hundreds of products you could make with UBQ today," Albert said. "We're talking about millions of tons worth of material that could be replaced."

Supercool Takeaway

Recycling failed because we built infrastructure for perfect behavior. UBQ succeeds because it's designed for reality—no sorting, no contamination concerns, no new equipment needed.

Operator Takeaways

Design for the world as it is. Don't ask customers to change processes, replace equipment, or retrain staff. Fit into existing systems seamlessly.

Go dark until validation is absolute. UBQ spent 10 years in stealth. That patience built credibility no marketing could manufacture.

Match incumbent economics. UBQ costs the same as virgin plastic—adoption happens when there’s no price premium.

This Week’s Podcast Episode

Stop Sorting: How UBQ Materials Uses 100% Of Your Trash

🎙️ Listen on Apple, Spotify, YouTube, and all other platforms.

↓

Stat of the Week: 21%

The percentage of recyclables in America that actually get recycled. The other 79% ends up in landfills despite our best intentions and sorting efforts.

Seven out of ten cardboard boxes

Three out of four milk jugs

Four out of five steel cans

Three out of four tons of mixed paper

Seven out of ten glass, aluminum, and PET bottles

Quote of the Week:

Every time we talk about sustainability, there's always one other word attached to it—how much is the premium? UBQ can compete with oil-based polymers at any point in the cycle, whether oil is at $20 or $100. The way I describe it is you get all the sustainability for free.

↓

🌐 The Climate Adoption Playbook

Recycling was sold to us as a silver bullet. It never was.

The infrastructure was built around assumptions that sounded good but never matched reality: consumers would sort perfectly, contamination could be managed, and degraded materials would retain value through multiple cycles.

We built a system that works beautifully in theory and fails consistently in practice.

UBQ's approach offers a different framework: skip sorting entirely, welcome contamination, and design a material that improves with age rather than degrades.

That shift—from asking the world to behave differently to building solutions that align with how the world works—is the heart of climate adoption strategy.

The Climate Adoption Playbook teaches it: how to design solutions that remove friction, align with existing incentives, and scale through ease rather than education.

For founders, go-to-market leaders, and operators bringing climate solutions to market, this course provides the frameworks to accelerate adoption in the real world—not the one we wish existed.

👉 Learn more at getsuper.cool/playbook.

↓

The Material Science Revolution

A new generation of companies is developing plastic alternatives from waste streams, natural sources (notably seaweed), agricultural byproducts, and biological processes. They're not asking people to use less plastic; they're producing materials that perform as well while returning safely to natural systems.

Sway – seaweed-based packaging

Sway makes thin-film packaging from seaweed that dissolves in water and biodegrades in soil. The material is designed to replace single-use plastics in applications like mailer bags and food wraps. Seaweed grows fast, requires no fertilizer or fresh water, and removes carbon as it grows.

Loliware – edible and compostable straws

Loliware produces straws and other food-contact items made from seaweed that can be eaten or composted. The company has secured partnerships with major brands looking to eliminate plastic straws.

Notpla – seaweed packaging for liquids

Notpla makes edible sachets and coatings from seaweed and plants that can hold liquids and sauces. The capsules have been used at marathons to replace plastic water bottles and by food delivery services to package condiments. They disappear in weeks, not centuries.

AirCarbon – carbon-negative bioplastic

Newlight Technologies produces AirCarbon, a thermoplastic made by feeding greenhouse gases to microorganisms that convert them into a polymer. The result is a material that's carbon-negative by definition and can replace traditional plastics in products ranging from fashion accessories to foodware.

↓

AEC Tech + AI Newsletter: Climate-Positive Panels Transform Homebuilding

↓

Interested in Advertising with Supercool?

Connect with future-forward decision-makers seeking next-gen climate innovations. Reach out to discuss how Supercool’s platform can help. Just hit reply to this email.

↓

Not yet subscribed to Supercool?

Click the button below for weekly updates on real-world climate solutions that cut carbon, boost the bottom line, and improve modern life.

🌐